Walk-On Glass

we've been supplying architects and installers with walk-on glass since 1993

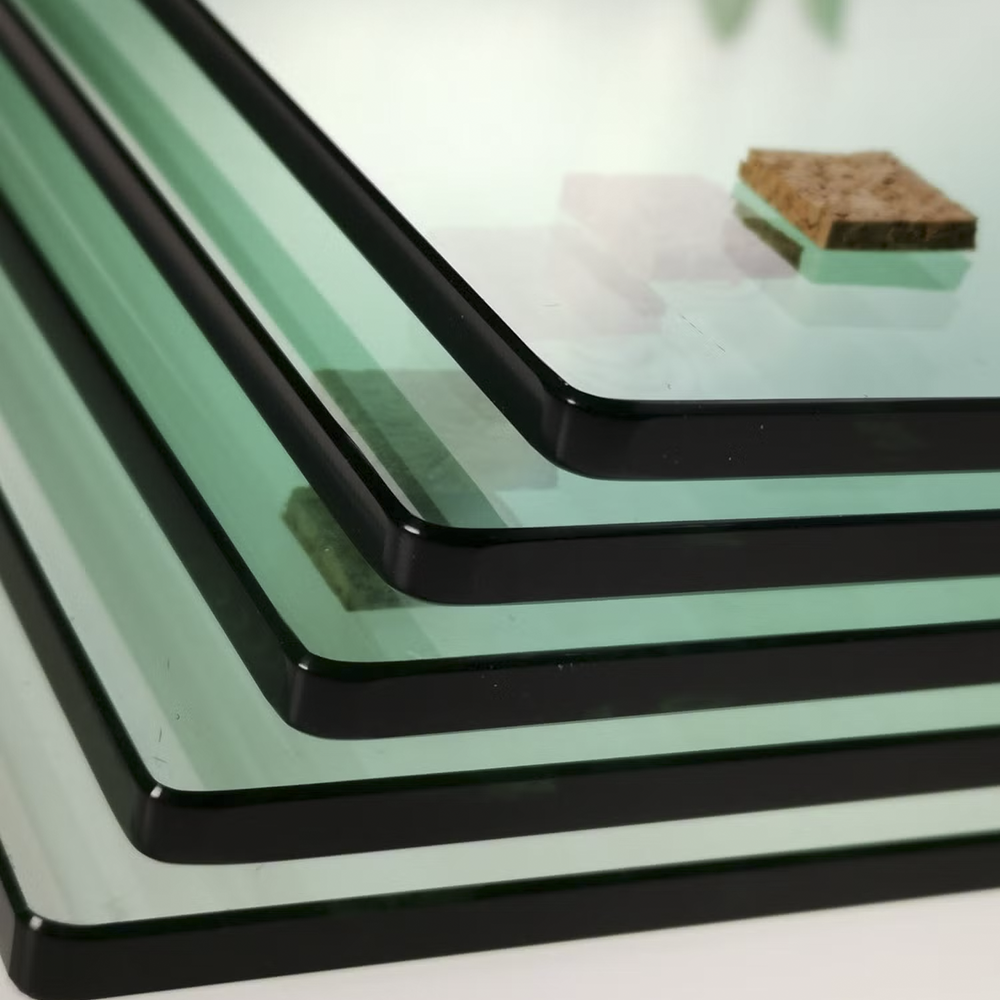

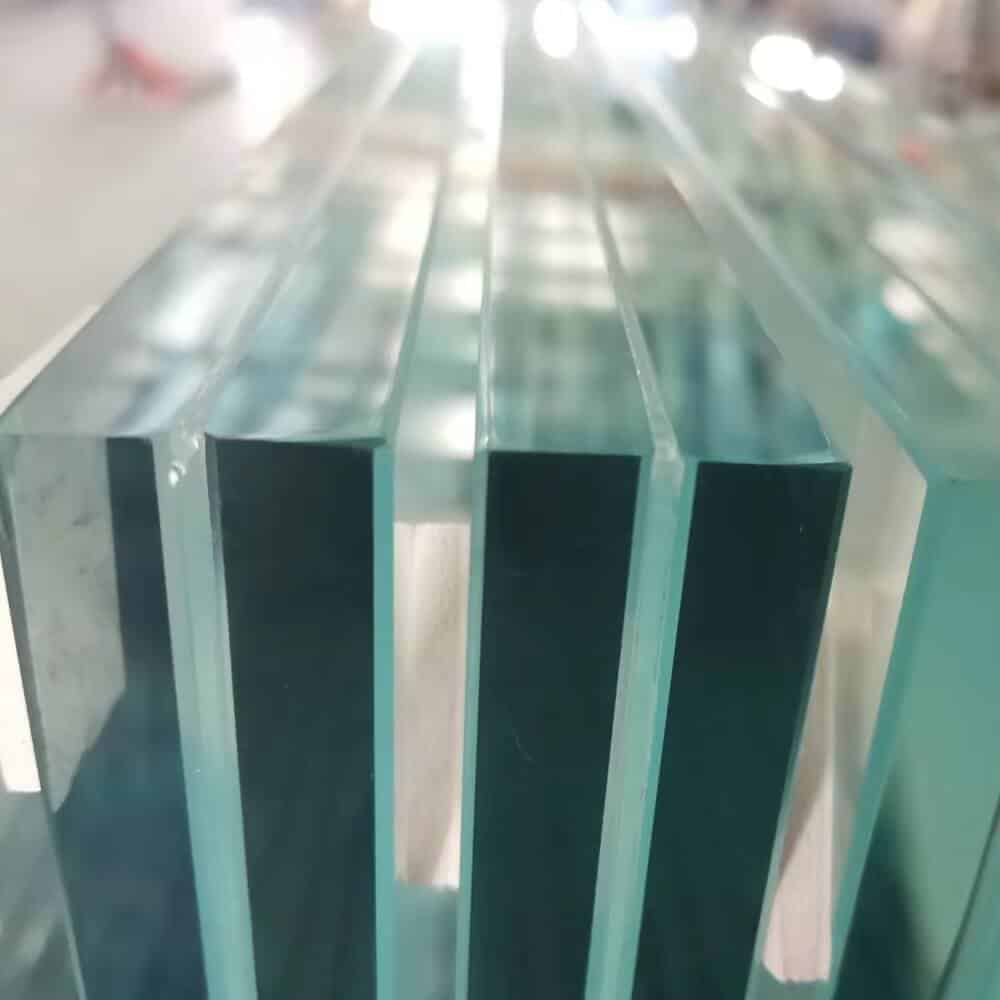

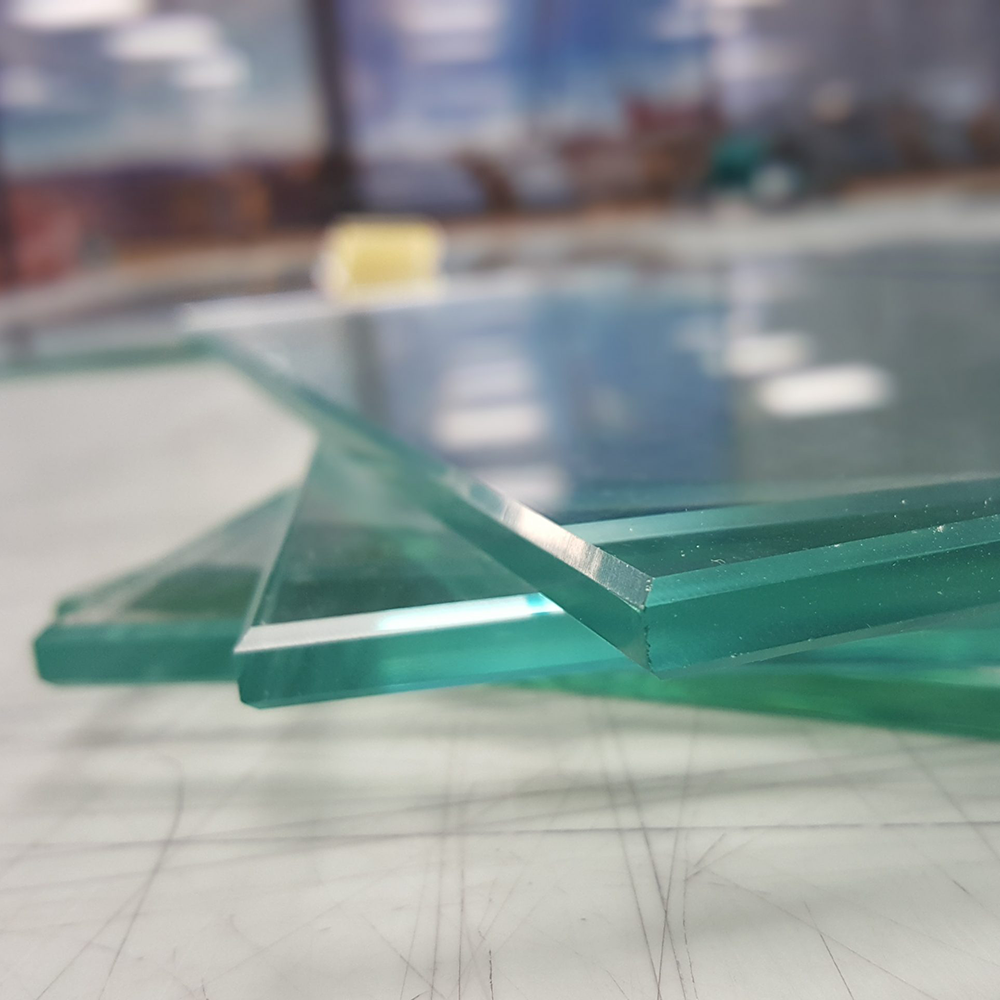

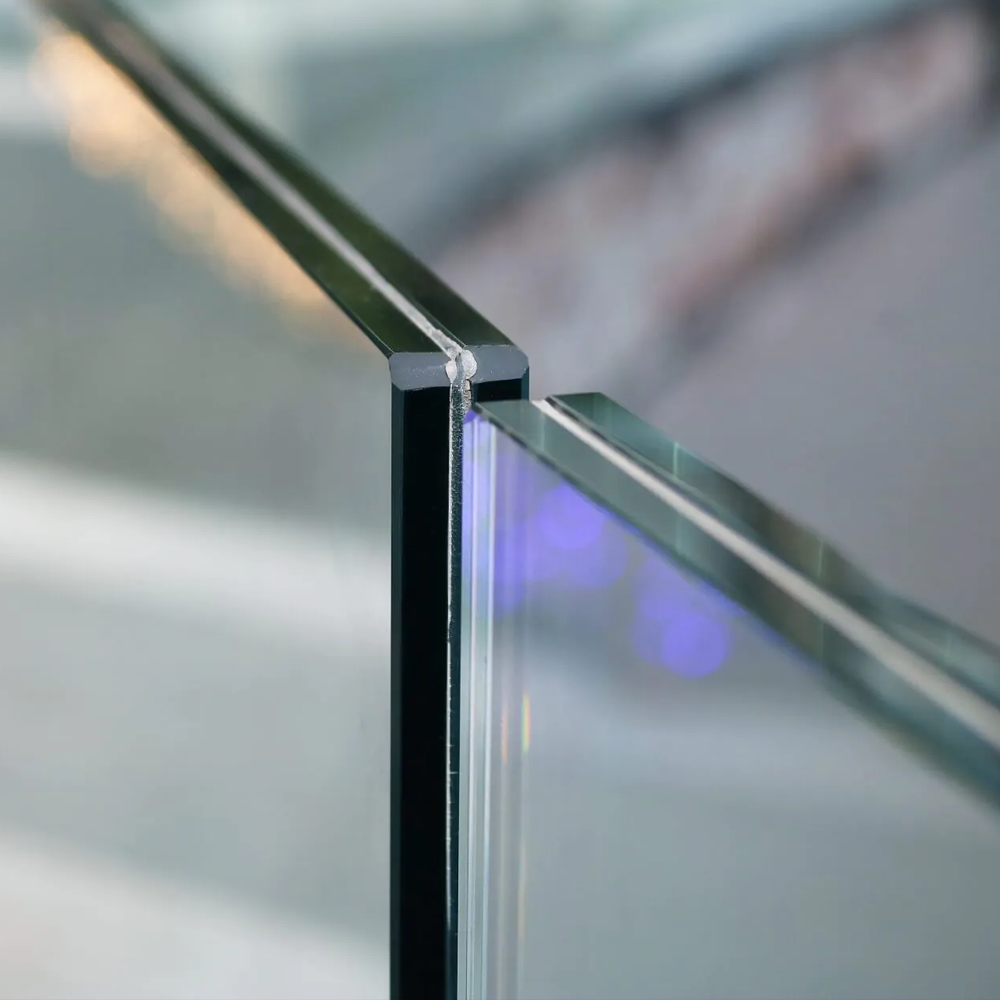

Walk-on glass typically consists of multiple layers of toughened (tempered) and laminated glass, bonded together to achieve the necessary strength and safety. This construction ensures that the glass can withstand significant loads and impact, making it suitable for flooring applications. For instance, toughened laminated glass is up to five times stronger than standard glass, providing a robust and durable surface for walking.

Safety

High-quality walk-on glass often includes safety features that block up to 99% of harmful UV radiation, protecting interiors from fading and occupants from excessive UV exposure.

Sound Dampening

The laminated layers can also provide acoustic insulation, reducing noise transmission between different building levels.

Melting and Refining

The raw materials are precisely weighed, mixed, and fed into a furnace operating at temperatures around 1,500°C (2,732°F). At this high temperature, the mixture melts into a homogeneous molten glass. Refining processes remove any bubbles or impurities, ensuring clarity and uniformity in the final product.

Security

Constructed from multiple layers of toughened (tempered) and laminated glass, walk-on glass is engineered to withstand significant loads and impacts, ensuring durability and safety.

Applications

Due to its durability and safety properties, toughened glass is widely used in various applications, including:

Residential Spaces

Installing glass floors in homes can create a modern and open feel, allowing natural light to penetrate deeper into living areas

Commercial Properties

Incorporating walk-on glass panels in offices, retail spaces, or museums can enhance the visual appeal and create a sense of openness, while also serving functional purposes such as illuminating lower levels.

Bridges and Terraces

Glass flooring is also used in bridges and terraces, providing a unique experience of walking on air and offering unobstructed views below.

Manufacturing Process

Assembly

Two or more glass sheets are thoroughly cleaned and then layered with the PVB interlayer

Float Glass Formation

The molten glass is then directed onto a bath of molten tin in a process known as the float glass method. Here, the glass spreads out and forms a continuous, flat ribbon with uniform thickness. As it moves along the tin bath, the glass gradually cools and solidifies while maintaining parallel surfaces, resulting in high optical quality.

Laminating

To ensure safety and structural integrity, multiple layers of tempered glass are laminated together:

Complete Glass Solutions

Our Glass product range

Heated Glass

European Glass supply electrically heated glass products to commercial and domestic properties.

Acoustic Laminated Glass

High-performance glazing solution specifically designed to reduce external noise

Toughened Glass

We have two Glaston Bending Furnaces capable of 4 metre bends.

Laminated Glass

Laminated glass is a type of safety glass composed of two or more layers of glass bonded together.

Walk-On Glass

FC500 GLaston Toughening Furnace - the largest in the world.

Fire Rated Glass

Fire-rated glass is a specialized glazing material engineered to prevent the spread of flames and smoke during a fire.

Heat Soak Glass

Heat-soaked glass refers to tempered glass that has undergone a heat soak test.

Bend Glass

Bent glass, also known as curved glass, is glass that has been shaped into a curved form

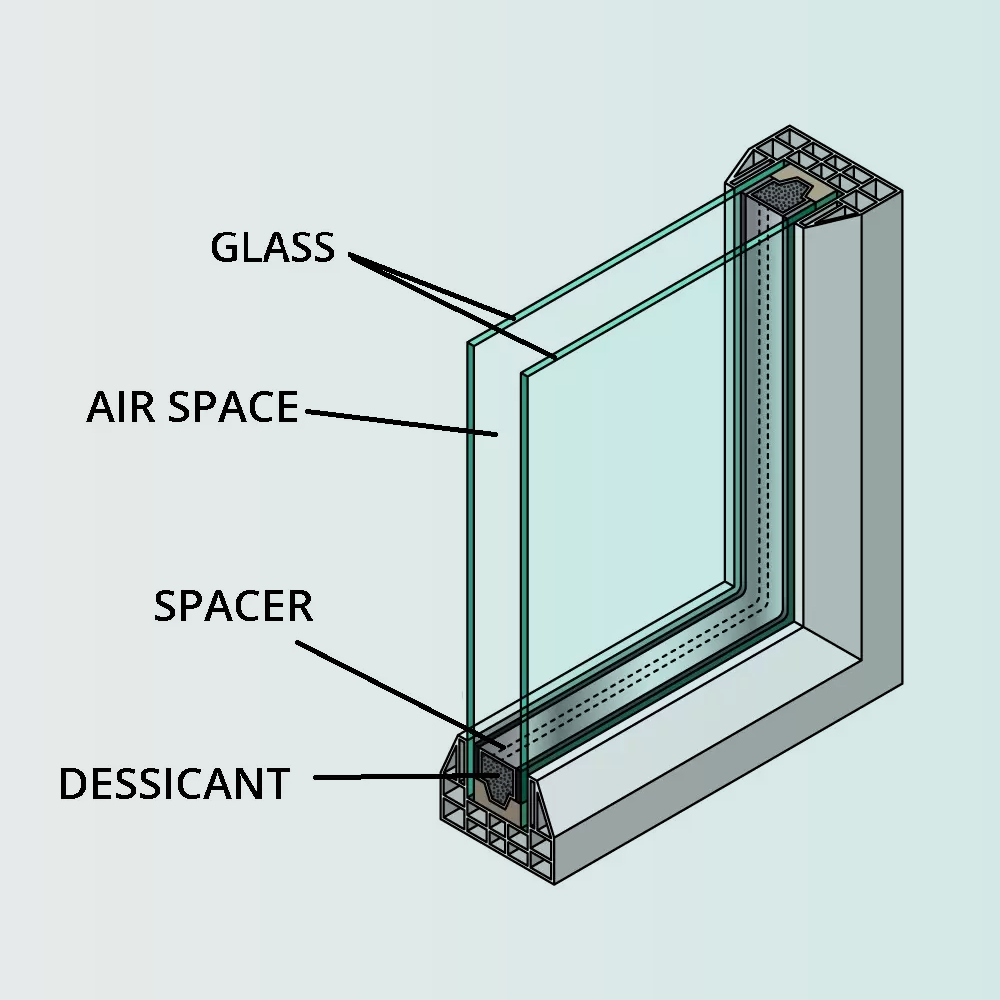

Double Glazed Units - DGU

Boost energy efficiency and acoustic performance in buildings.

Heat Strengthened Glass

Controlled heating and cooling to increase strength and thermal resistance.

Toughened Laminated Glass

High-performance safety glass made by bonding more layers of toughened glass.