Acoustic Laminated Glass

High-performance glazing solution specifically designed to reduce external noise

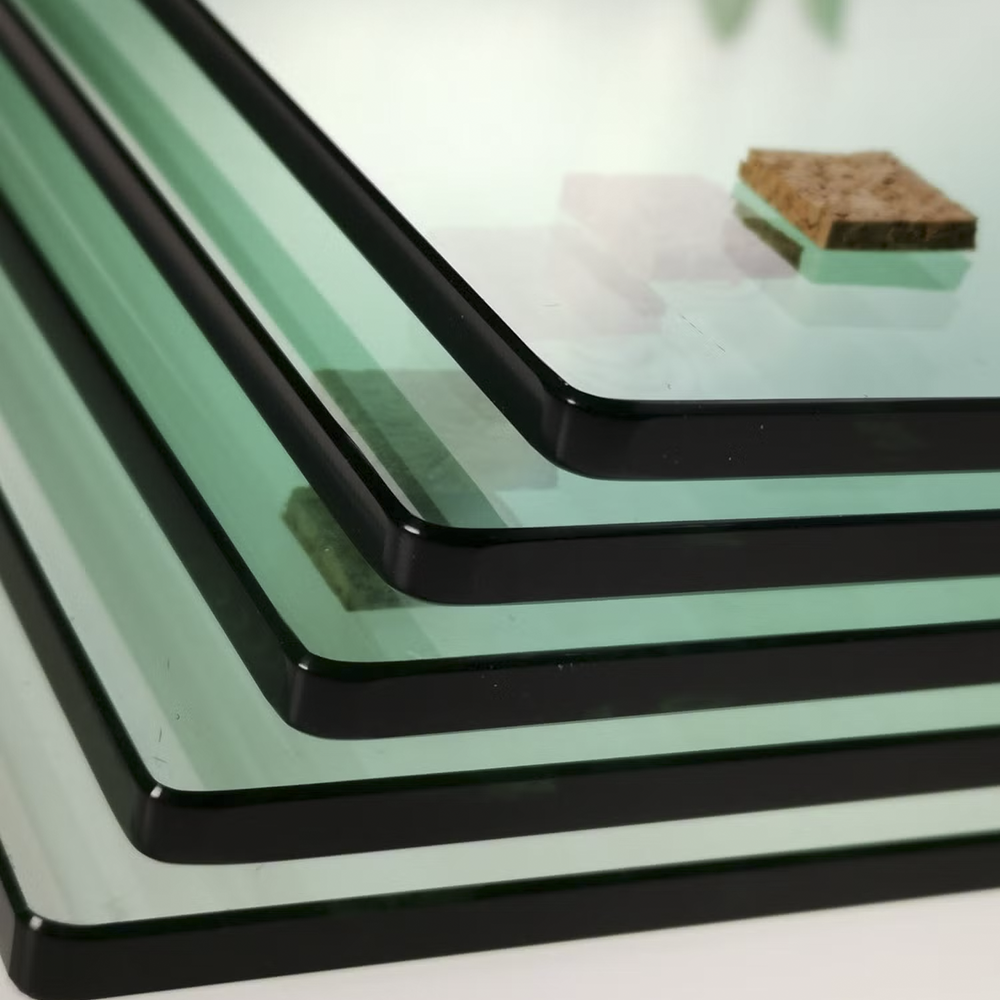

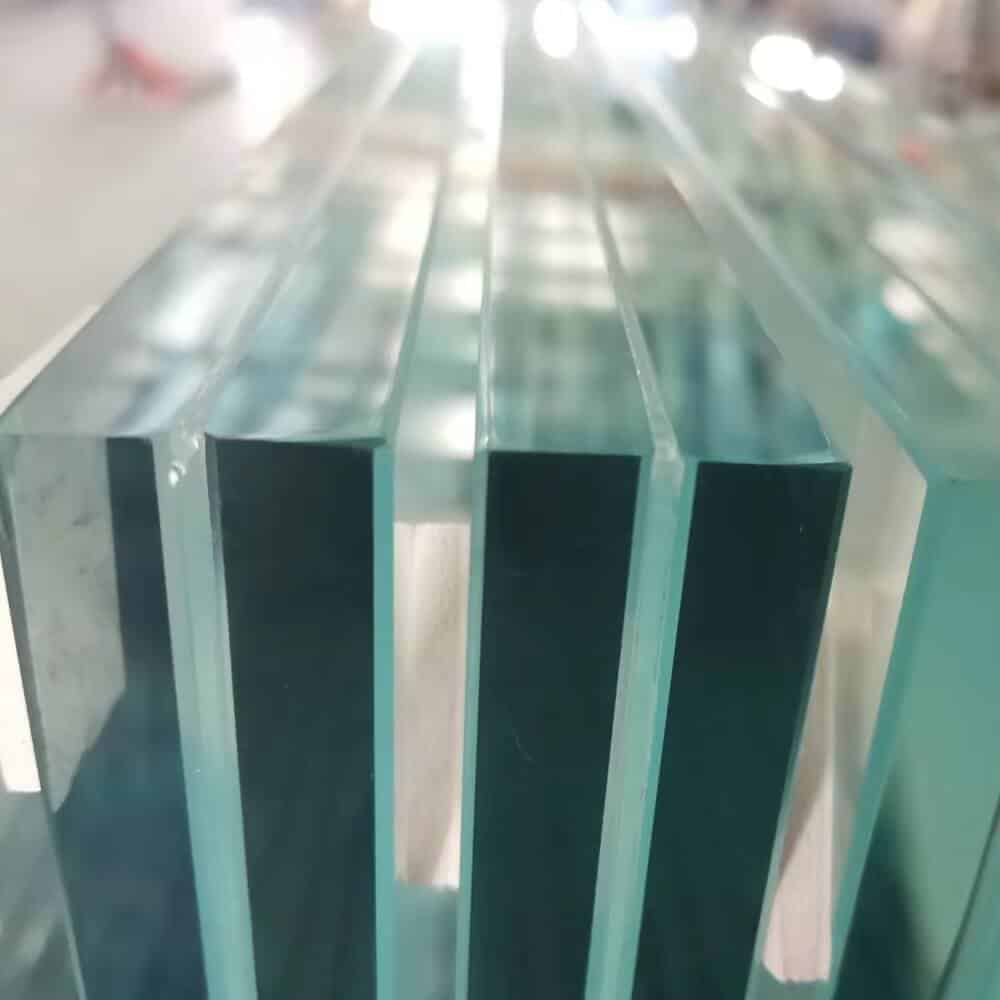

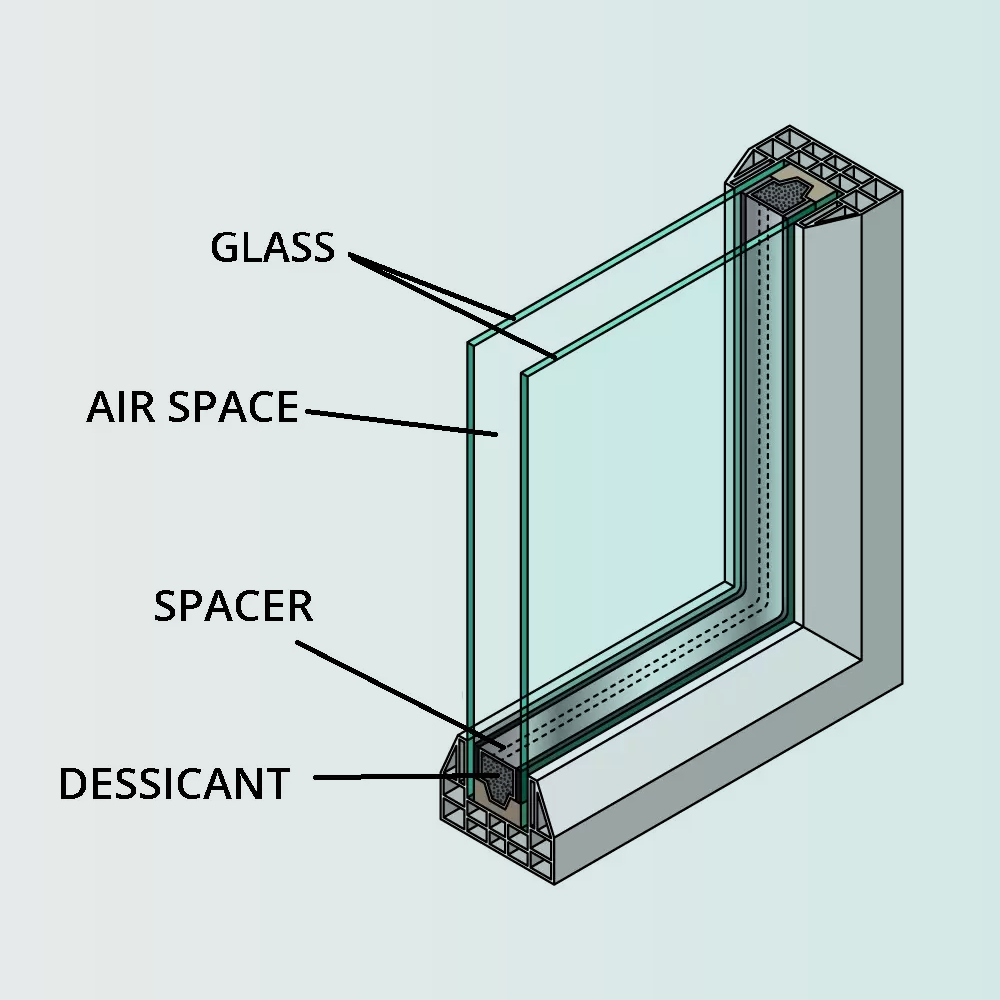

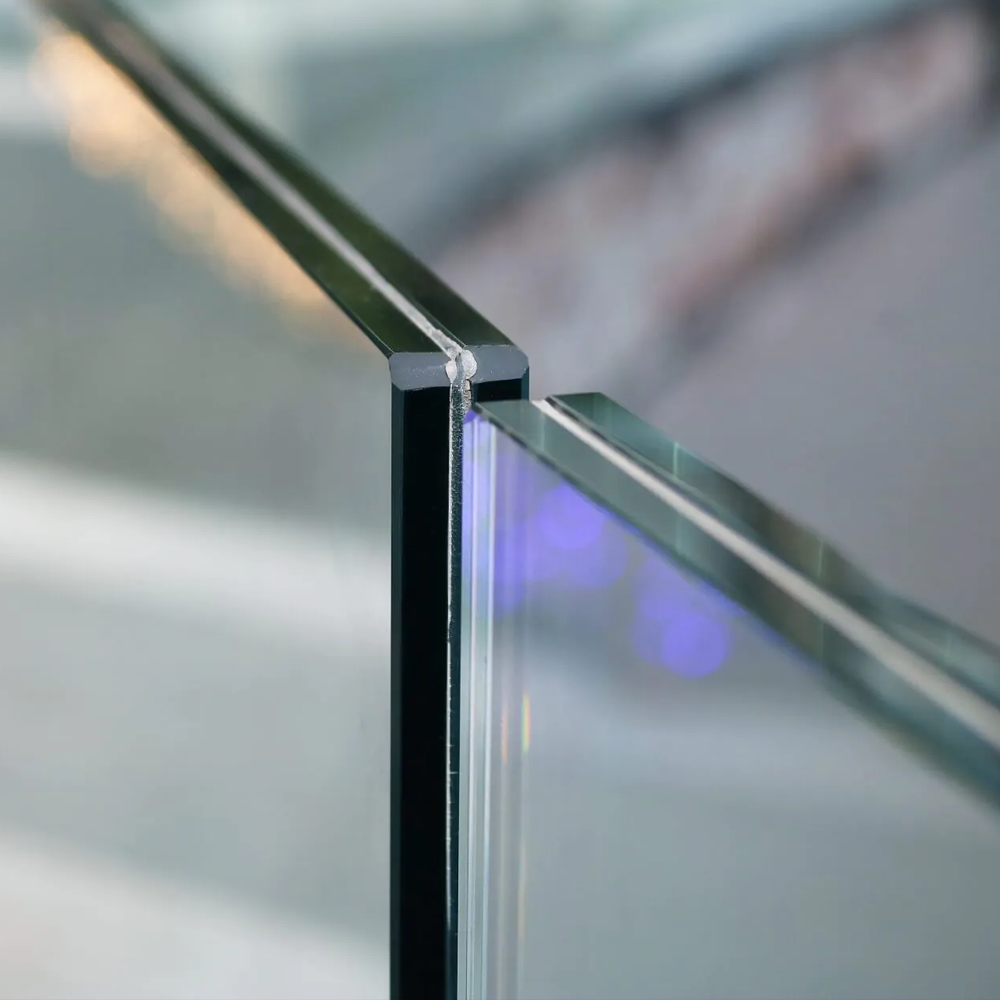

Acoustic glass, also known as acoustic laminated glass, is a High-performance glazing solution specifically designed to reduce external noise. It consists of two or more layers of glass bonded together with a special acoustic interlayer (typically acoustic PVB), which works to absorb and block sound vibrations. This makes it an ideal choice for buildings in noisy environments such as near roads, railways, airports, or factories.

Excellent noise reduction

The special acoustic interlayer between the glass panes absorbs and dampens sound waves, helping block unwanted noise from traffic, construction, or crowded spaces.

Maintains high safety standards

Even if the glass breaks, the interlayer holds the pieces together, reducing the risk of injury and improving security compared to standard glass.

Blocks harmful UV rays

The interlayer can filter out up to 99% of damaging ultraviolet radiation, helping protect interiors, furniture, and fabrics from fading.

Improves indoor comfort and peace

the glass is specially engineered to reduce the amount of noise entering a building from the outside.

Available in various thicknesses and combinations

that Acoustic Laminated Glass can be customized to meet different performance, safety, and design needs.

Applications

Due to its durability and safety properties, Acoustic Laminated Glass is widely used in various applications, including:

Recording studios and Cinemas

Enhances sound quality by keeping unwanted external noise out and preventing sound leakage.

Offices and Meeting rooms

Improves privacy by reducing sound transmission, ensuring conversations stay confidential.

Hotels, Hospitals, and Schools

Maintains a peaceful atmosphere for rest, recovery, or learning, even in noisy surroundings.

Manufacturing Process

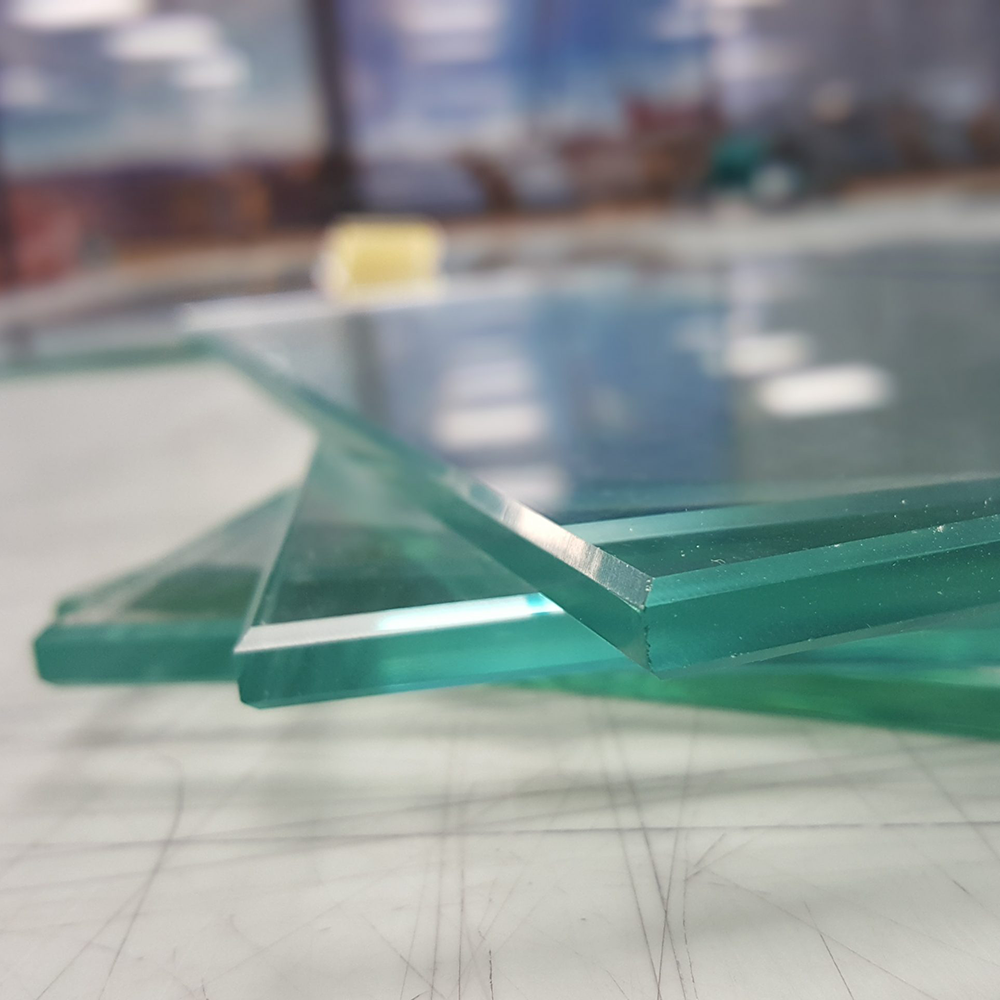

Glass Selection

High-quality float glass is chosen in the required thickness.

Interlayer Placement

A specially formulated acoustic PVB interlayer is placed between the glass sheets.

Assembly

The glass and interlayer are stacked and aligned precisely.

Heat & Pressure Treatment (Autoclaving)

The assembly is heated and pressurized in an autoclave to bond the layers into a single solid pane, eliminating air bubbles.

Quality Inspection

The final glass is checked for clarity, strength, and soundproofing performance before shipment.

Complete Glass Solutions

Our Glass product range

Heated Glass

European Glass supply electrically heated glass products to commercial and domestic properties.

Toughened Glass

We have two Glaston Bending Furnaces capable of 4 metre bends.

Laminated Glass

Laminated glass is a type of safety glass composed of two or more layers of glass bonded together.

Walk-On Glass

FC500 GLaston Toughening Furnace - the largest in the world.

Fire Rated Glass

Fire-rated glass is a specialized glazing material engineered to prevent the spread of flames and smoke during a fire.

Heat Soak Glass

Heat-soaked glass refers to tempered glass that has undergone a heat soak test.

Bend Glass

Bent glass, also known as curved glass, is glass that has been shaped into a curved form

Double Glazed Units - DGU

Boost energy efficiency and acoustic performance in buildings.

Heat Strengthened Glass

Controlled heating and cooling to increase strength and thermal resistance.

Toughened Laminated Glass

High-performance safety glass made by bonding more layers of toughened glass.

Acoustic Laminated Glass

High-performance glazing solution specifically designed to reduce external noise