Heat Soak Glass

Choose European Glass Group for high-quality, heat-strengthened glass

Heat-soaked glass refers to tempered glass that has undergone a heat soak test to reduce the risk of spontaneous breakage due to nickel sulfide (NiS) inclusions. This process involves placing the tempered glass inside a chamber and raising the temperature to approximately 550°F (287°C) to accelerate NiS expansion. Glass containing NiS inclusions is likely to break during this process, thereby reducing the risk of potential field breakage.

Enhanced Safety

By subjecting tempered glass to elevated temperatures during the heat soak process, NiS inclusions are more likely to cause breakage within the controlled environment of the heat soak chamber. This reduces the risk of spontaneous breakage in installed glass, enhancing overall safety

Quality Assurance

The heat soaking process serves as a quality control measure, ensuring that glass panels with potential impurities are identified and eliminated before installation.

Durability

While tempered glass is already stronger than annealed glass, heat-soaked glass offers an additional layer of reliability by minimizing the chances of unexpected failures due to internal impurities.

Applications

Due to its durability and safety properties, toughened glass is widely used in various applications, including:

Facades and Curtain Walls

In high-rise buildings, airports, and stadiums, heat-soaked glass is used for facades and curtain walls to mitigate the risk of glass falling from heights, thereby ensuring public safety.

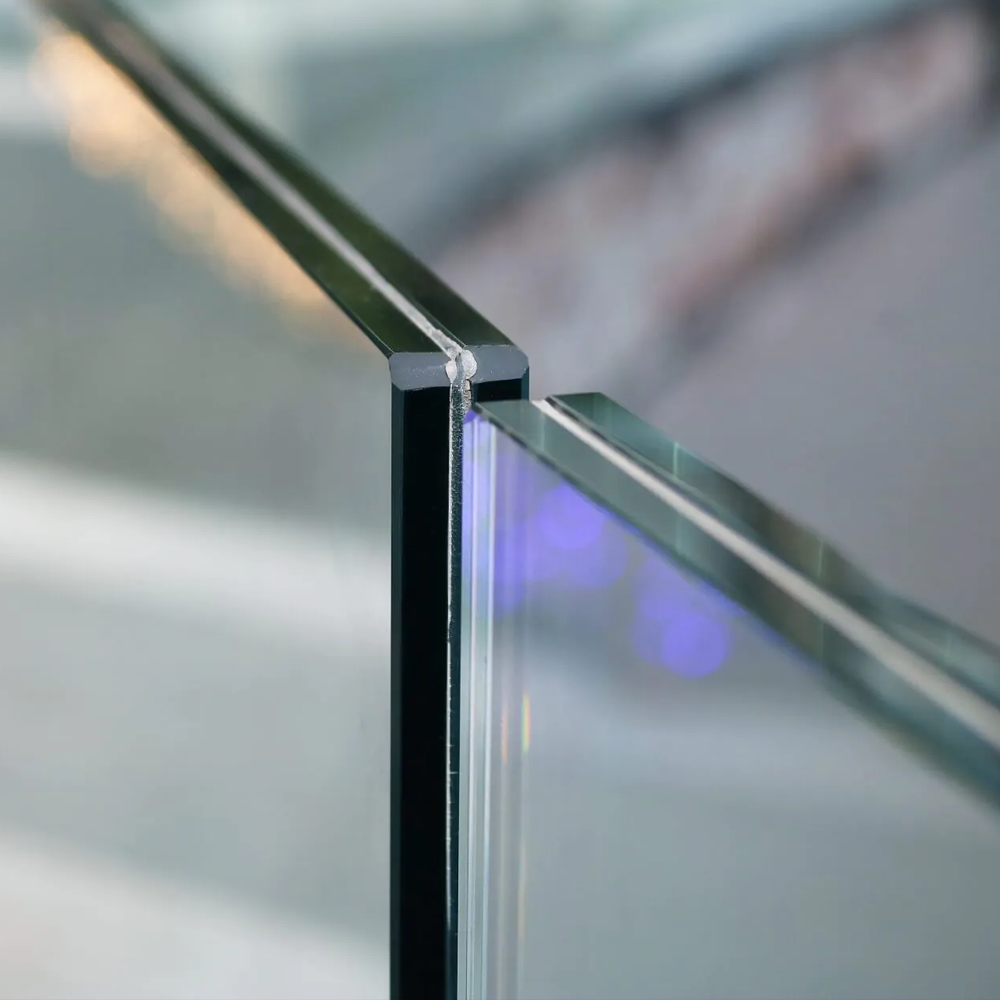

Balustrades and Railings

Heat-soaked glass is ideal for balustrades and railings in areas with high foot traffic, such as offices, restaurants, and commercial buildings, due to its enhanced strength and resistance to impact.

Doors and Windows

For doors and windows in commercial establishments where security is a concern, heat-soaked glass offers increased resistance to break-ins and vandalism.

Manufacturing Process

Heating Phase

The oven temperature is gradually increased to approximately 290°C (554°F). This heating rate is controlled to ensure uniform temperature distribution and to prevent thermal shock to the glass panels.

Soaking Phase

Once the target temperature is reached, it is maintained for a specified duration, typically ranging from 2 to 8 hours. This "soaking" period allows any NiS inclusions present in the glass to undergo a phase transformation, which can lead to the breakage of affected panels within the controlled environment of the oven

Inspection and Quality Control

Once cooled, the glass panels are inspected for any signs of breakage. Panels that have remained intact are considered to have passed the heat soak test and are deemed suitable for installation. This process significantly reduces the likelihood of spontaneous breakage due to NiS inclusions in the field.

Complete Glass Solutions

Our Glass product range

Heated Glass

European Glass supply electrically heated glass products to commercial and domestic properties.

Acoustic Laminated Glass

High-performance glazing solution specifically designed to reduce external noise

Toughened Glass

We have two Glaston Bending Furnaces capable of 4 metre bends.

Laminated Glass

Laminated glass is a type of safety glass composed of two or more layers of glass bonded together.

Walk-On Glass

FC500 GLaston Toughening Furnace - the largest in the world.

Fire Rated Glass

Fire-rated glass is a specialized glazing material engineered to prevent the spread of flames and smoke during a fire.

Heat Soak Glass

Heat-soaked glass refers to tempered glass that has undergone a heat soak test.

Bend Glass

Bent glass, also known as curved glass, is glass that has been shaped into a curved form

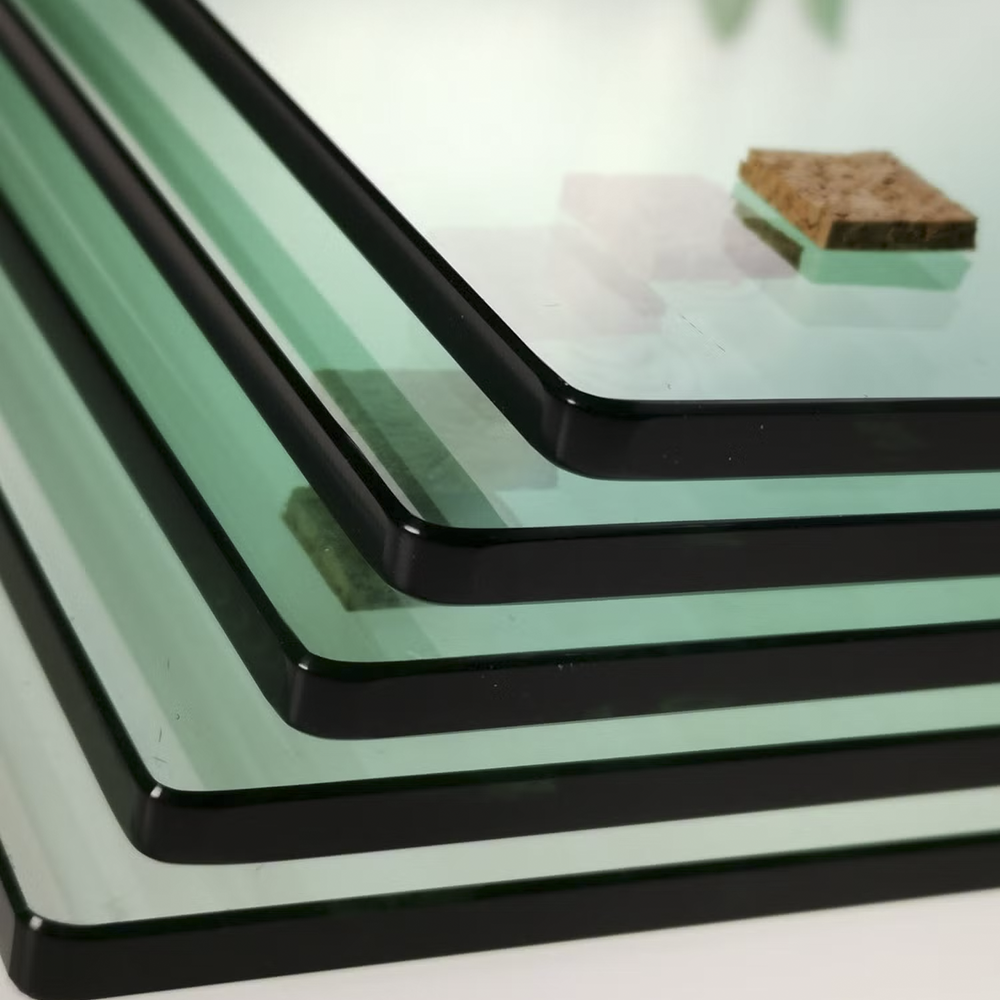

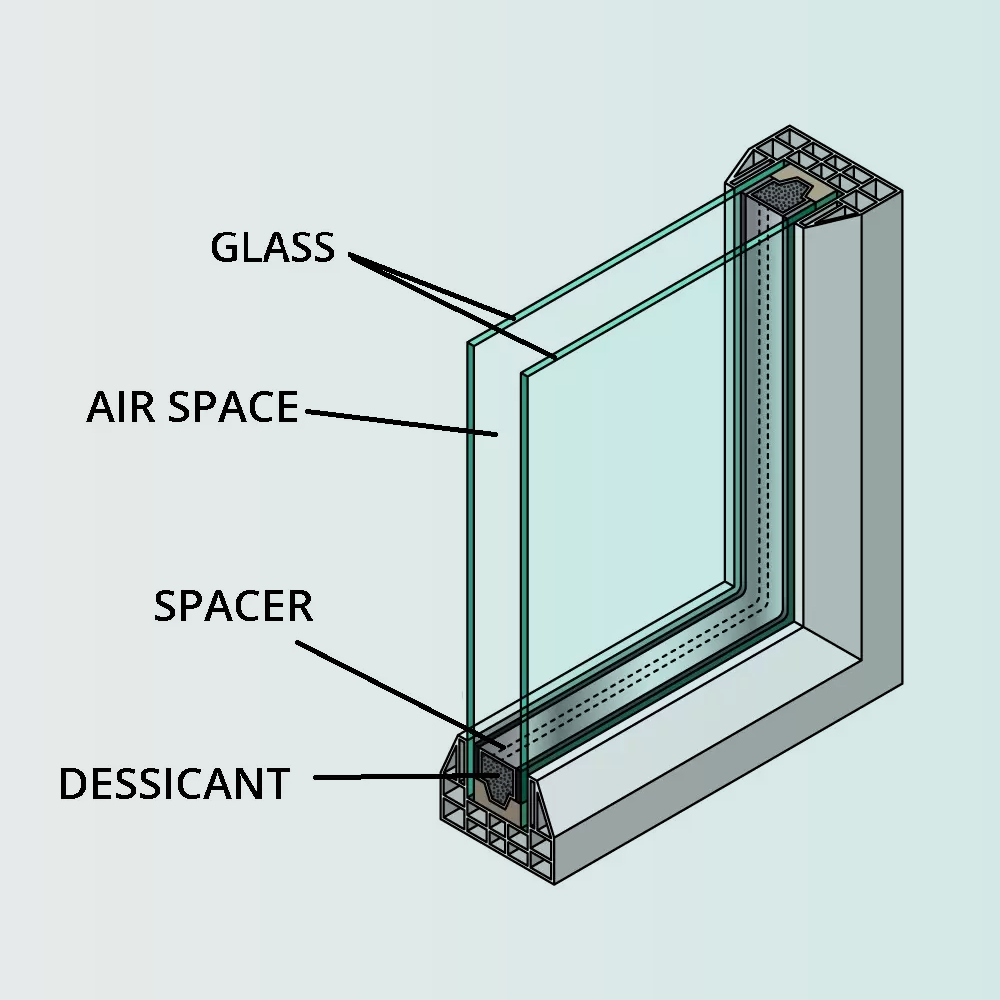

Double Glazed Units - DGU

Boost energy efficiency and acoustic performance in buildings.

Heat Strengthened Glass

Controlled heating and cooling to increase strength and thermal resistance.

Toughened Laminated Glass

High-performance safety glass made by bonding more layers of toughened glass.