Toughened Laminated Glass

Select high-strength and reliable Toughened Laminated Glass from one of the UK’s trusted glass suppliers

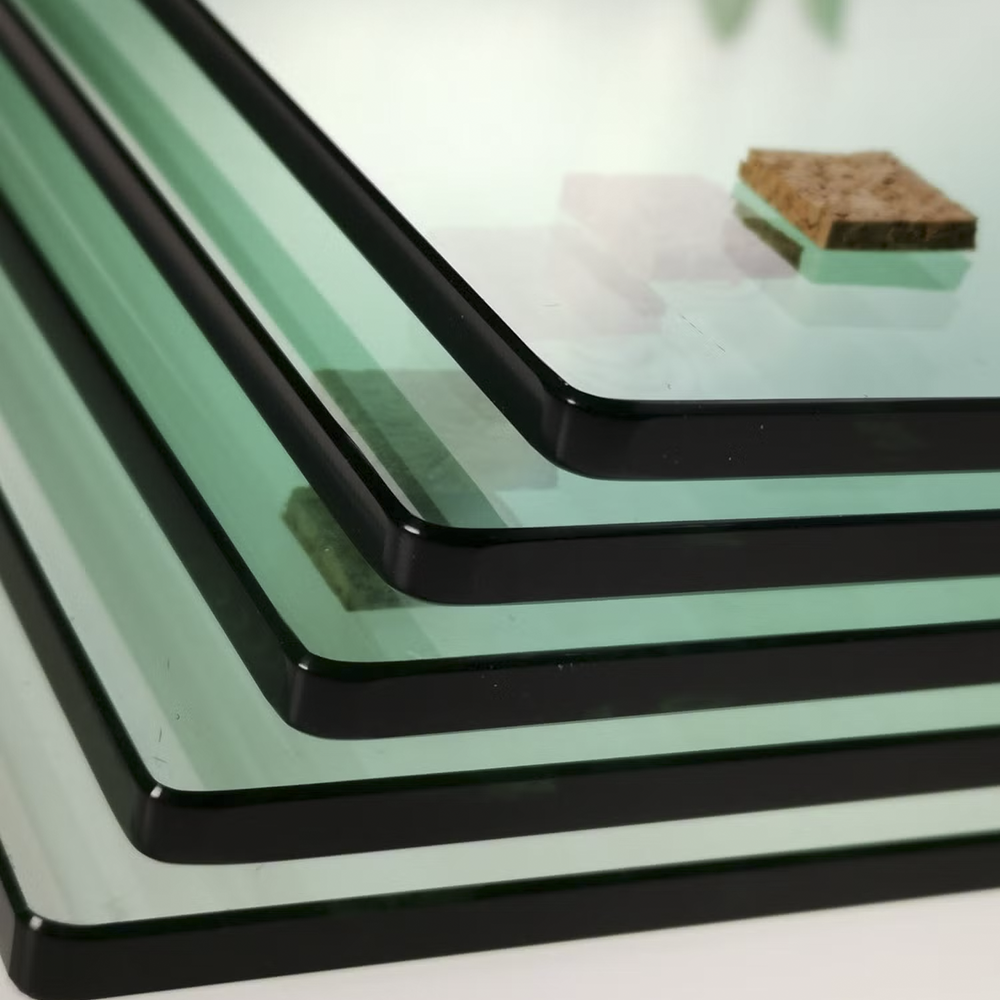

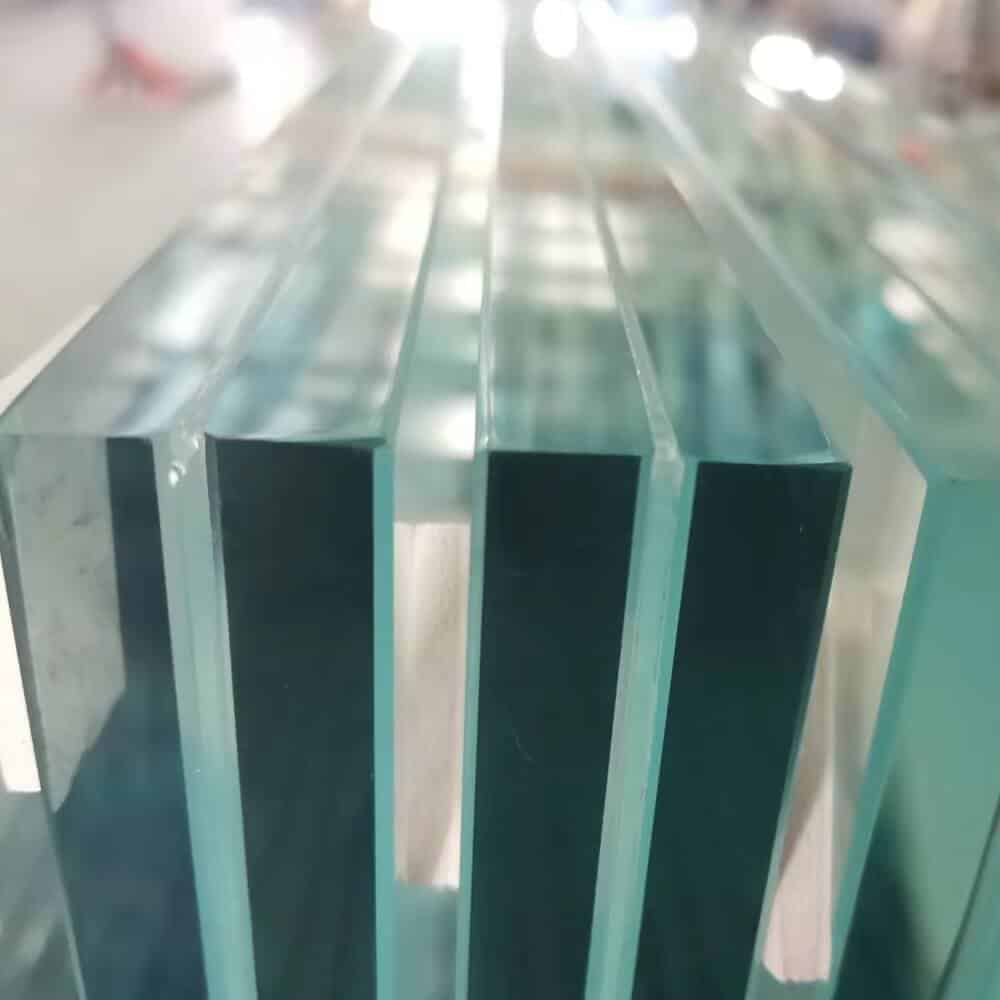

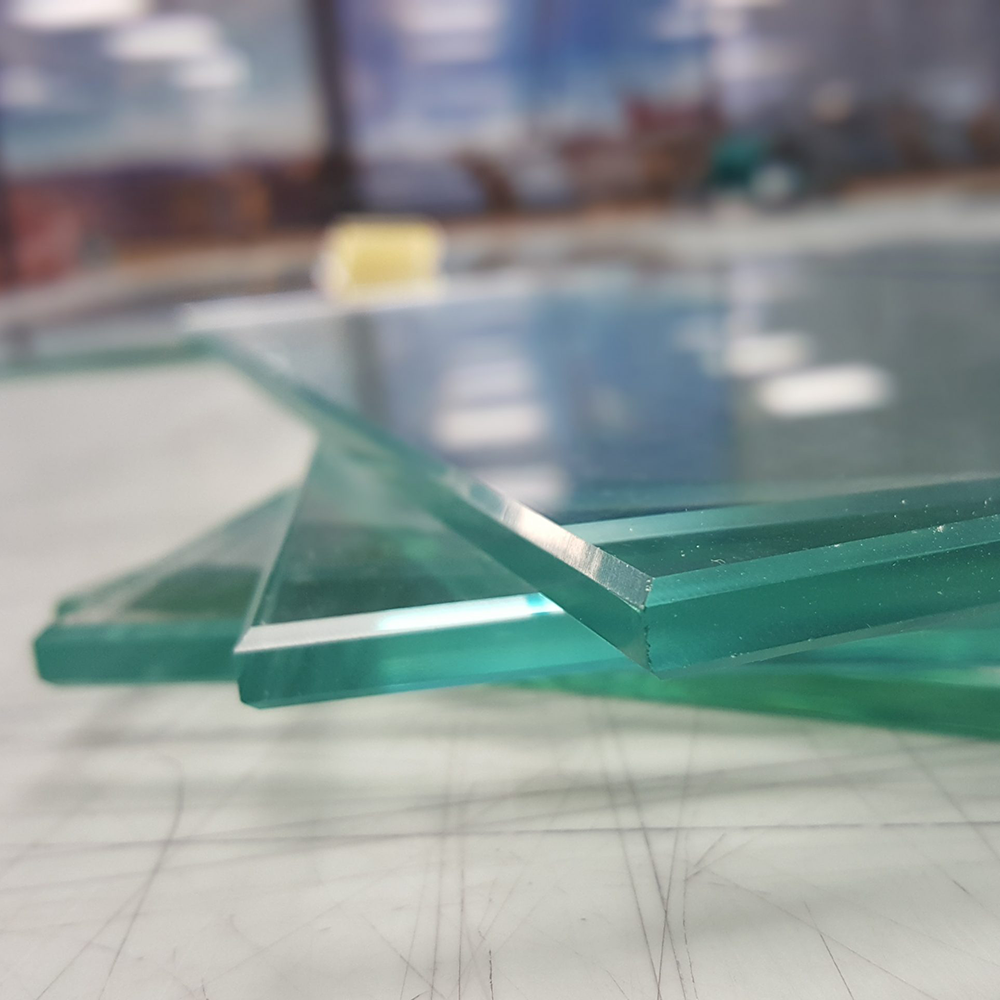

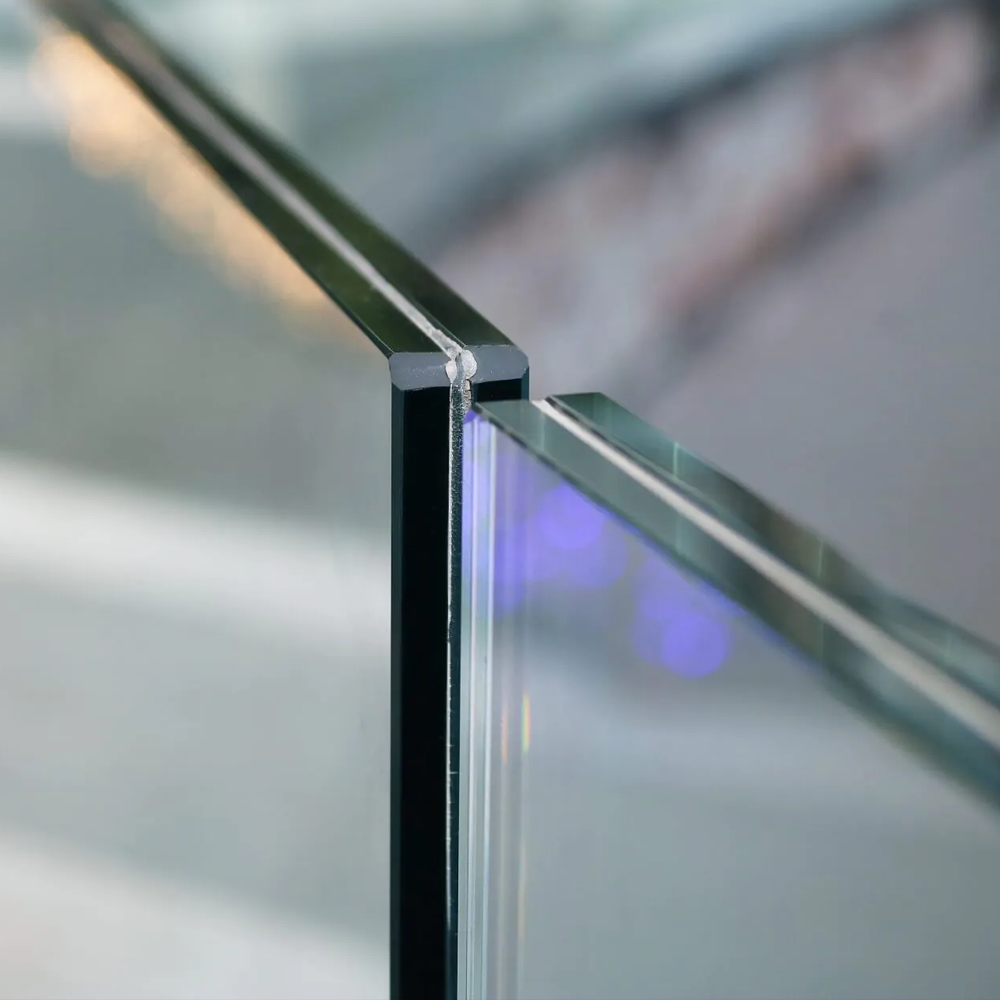

Toughened Laminated Glass is a high-performance safety glass made by bonding two or more layers of toughened glass with a durable interlayer such as PVB (Polyvinyl Butyral) or SGP (SentryGlas®️ Plus). It offers superior strength, security, and sound insulation—ideal for structural and architectural use.

Exceptional Impact Resistance

Designed to withstand strong force without shattering dangerously.

Enhanced Safety

Stays in place when broken for added safety.

Acoustic & UV Protection

Minimizes external noise and blocks up to 99% of harmful UV rays, helping protect interiors from fading.

Versatile Applications

Ideal for balustrades, floors, canopies, facades, and curtain wall systems, combining strength with style.

Available Interlayers

PVB (Polyvinyl Butyral), SGP (SentryGlas Plus).

Applications

The Toughened Laminated Glass delivers robust safety features (like impact resistance and holding together when shattered), while also maintaining a clean, elegant, and modern design suitable for architectural use.

Due to its durability and safety properties, Toughened Laminated Glass is widely used in various applications, including:

Balustrades

Used as protective barriers along staircases, balconies, or terraces.

Floors

Glass flooring panels can create dramatic visual effects in architecture. The strength of laminated toughened glass makes it safe.

Canopies

Overhead glass canopies protect entrances or walkways from the weather.

Manufacturing Process

Toughening (Tempering) the Glass

First, two or more sheets of float glass are heated in a furnace to temperatures around 620–650°C and then rapidly cooled using high-pressure air. This process creates internal stresses that make the glass up to 5 times stronger than standard glass, while also ensuring that if it breaks, it shatters into small, blunt fragments for safety.

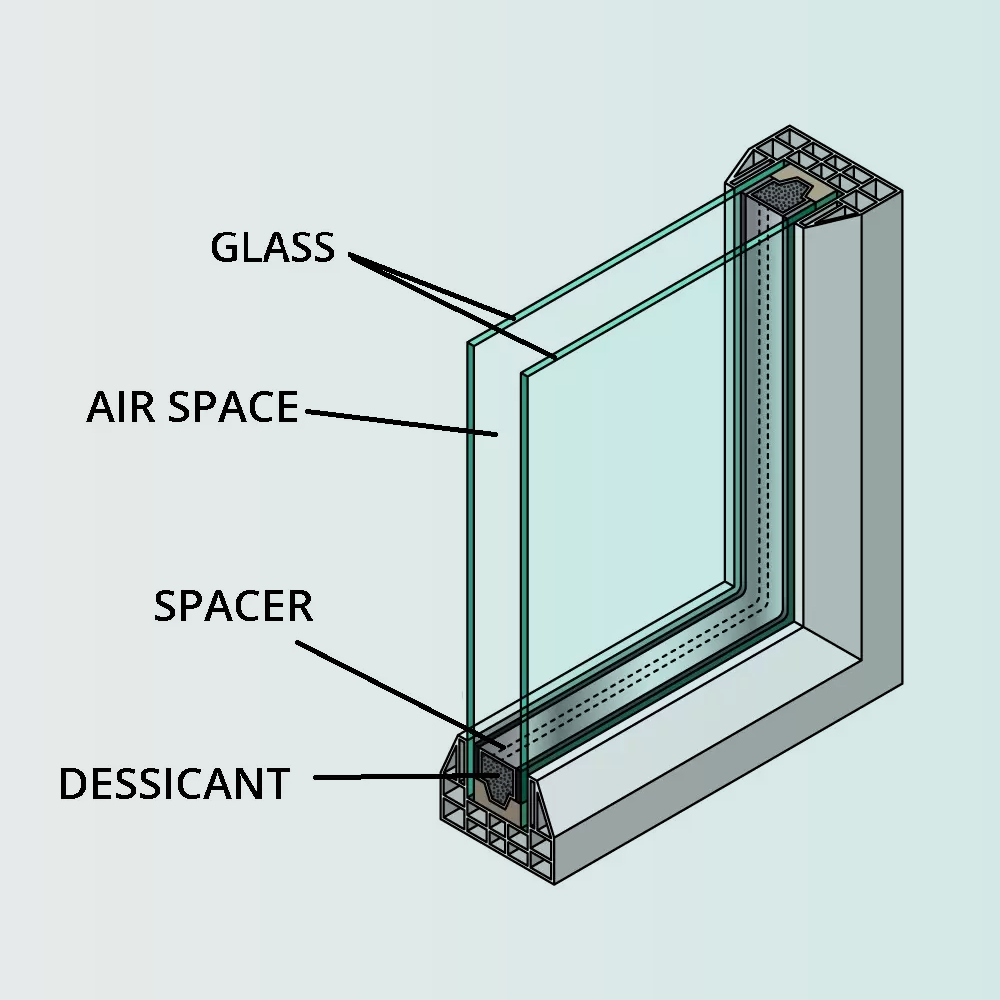

Preparing the Interlayer

A clear or tinted interlayer (usually PVB, EVA, or SGP) is cleaned and precisely cut to match the glass size. This interlayer acts as a bonding agent and adds strength, UV resistance, and sound insulation.

Autoclaving (Final Bonding)

The de-aired assembly is placed in an autoclave—a high-pressure oven—at temperatures between 130°C–150°C and pressures of up to 14 bars for around 30–60 minutes. This fully bonds the glass and interlayer into a single solid panel.

Quality Inspection & Finishing

Each unit is carefully inspected for optical clarity, lamination quality, and edge finishing. The glass may also be cut to size, drilled, or polished depending on client specifications.

Complete Glass Solutions

Our Glass product range

Heated Glass

European Glass supply electrically heated glass products to commercial and domestic properties.

Acoustic Laminated Glass

High-performance glazing solution specifically designed to reduce external noise

Toughened Glass

We have two Glaston Bending Furnaces capable of 4 metre bends.

Laminated Glass

Laminated glass is a type of safety glass composed of two or more layers of glass bonded together.

Walk-On Glass

FC500 GLaston Toughening Furnace - the largest in the world.

Fire Rated Glass

Fire-rated glass is a specialized glazing material engineered to prevent the spread of flames and smoke during a fire.

Heat Soak Glass

Heat-soaked glass refers to tempered glass that has undergone a heat soak test.

Bend Glass

Bent glass, also known as curved glass, is glass that has been shaped into a curved form

Double Glazed Units - DGU

Boost energy efficiency and acoustic performance in buildings.

Heat Strengthened Glass

Controlled heating and cooling to increase strength and thermal resistance.

Toughened Laminated Glass

High-performance safety glass made by bonding more layers of toughened glass.